Режим работы пункта самовывоза:

Пн-пт 10:00-21:00, сб-вс 10:00-19:00.

Колл-центр работает с 10 до 18 по будням.

- Описание

- Характеристики

- Сопутствующие товары

- Аналоги

- Отзывы (0)

Модель больше не поставляется, последние экземпляры на складе.

Похожая модель (аналог / замена): Приёмник Matek ELRS-R24-P6V

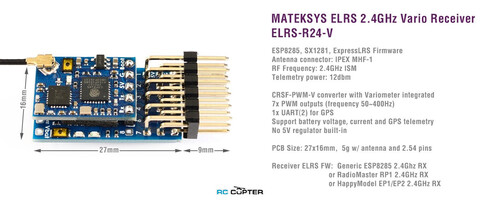

MATEKSYS ELRS 2.4GHz Vario Receiver ELRS-R24-V

- ESP8285, SX1281, ExpressLRS Firmware

- Антенный разъем: IPEX MHF-1

- Частота радиочастот: 2,4 ГГц ISM

- Мощность телеметрии: 12 дБм (16 мВт)

Преобразователь CRSF-PWM-V со встроенным вариометром

- 7x PWM выходов (частота 50~400 Гц)

- 1x UART(2) для GPS

- Поддерживает: напряжение батареи, ток и GPS-телеметрию

- Нет встроенного регулятора 5В

Размер печатной платы

- 27x16 мм, 5 г с антенной и 2,54 пинами

Подходящие прошивки приемника ELRS:

- Generic ESP8285 2.4Ghz RX

- RadioMaster RP1 2.4GHz RX

- HappyModel EP1/EP2 2.4GHz RX

Ссылка на производителя: https://www.mateksys.com/?portfolio=elrs-r24-v

MATEKSYS ELRS линейка приёмников

Считывание показаний Baro «Alt»

- Начиная с EdgeTX 2.7.1/OpenTX 2.3.15 и ExpressLRS 2.5, идентификатор телеметрии Baro Alt поддерживается в протоколе CRSF.

- Вам необходимо обновить передатчик, модуль ExpressLRS TX и приемник до последней версии.

- и обновить CRSF-PWM-V до версии V2.3.0 или более новой. https://www.mateksys.com/?portfolio=crsf-pwm#tab-id-6

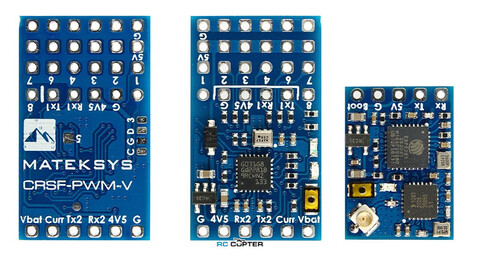

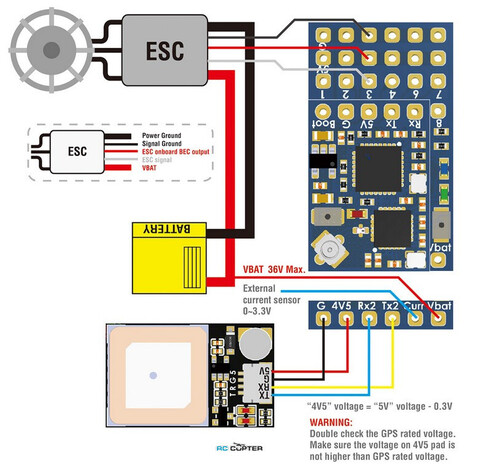

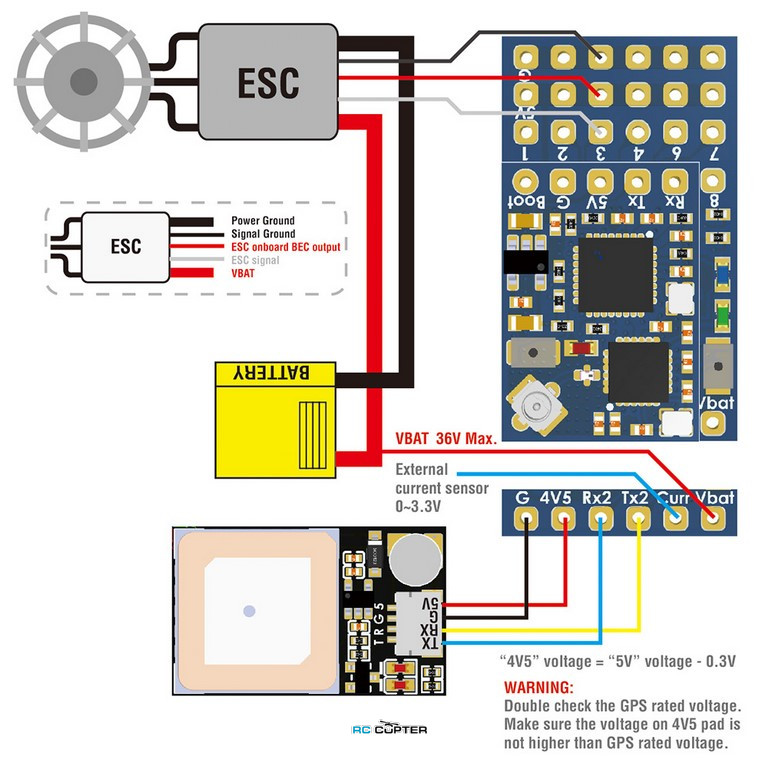

Нижний вариант печатной платы

На рынке существует еще один вариант нижней печатной платы CRSF-PWM. Площадка VBat находится рядом с CH «7», CH «8» - это просто площадка на нижней стороне. Маркировка шелкографией правильная на обеих версиях. Просто следуйте маркировке, чтобы подключить напряжение Vbat и сигнал CH8.

CRSF-PWM-V Характеристики

Выводы и колодки

- Tx1/Rx1(UART1) для встроенного приемника

- Tx2/Rx2(UART2) для GPS/обновления прошивки/установки параметров

- 1~8: ШИМ-выходы CH1~CH8

- Curr: сигнал датчика тока (0~3.3В)

- Vbat: 0~36В Определение напряжения батареи

- G: земля

- Напряжение на колодке 4v5 = 5V pad voltage -0.3V.

- Нет встроенного регулятора 5В, необходимо подавать питание на плату и приемник через внешний источник 5В

Отказоустойчивость (FW 2.0.0 или новее)

- CH3 предназначен для дросселя, значение Failsafe = 988 по умолчанию. вы можете изменить значение Failsafe для CH3 и других каналов с помощью следующих настроек.

- Убедитесь, что сигнал ESC отключен от платы CRSF-PWM перед началом настройки отказоустойчивости

- Соедините сигнальные колодки PWM1 и PWM2, затем включите питание платы CRSF-PWM и приемника.

- Значение отказоустойчивости будет сохранено автоматически после включения питания платы CRSF-PWM и получения сигнала CRSF. Светодиод быстро мигает 8 раз.

- Значение отказоустойчивости = значение ШИМ каждого канала передатчика при приеме сигнала CRSF платой CRSF-PWM.

- Удалите перемычку между PWM 1 и 2, тогда плата CRSF-PWM будет работать в нормальном режиме вывода ШИМ.

Состояние светодиодов

- медленно мигает: Плата CRSF-PWM не принимает сигнал CRSF, например, приемник не связан с передатчиком.

- горит постоянно: Плата CRSF-PWM и приемник работают нормально.

- 5x быстрых миганий после включения питания в течение 10 секунд: активен режим CLI

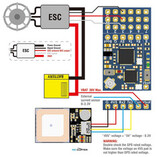

GPS-телеметрия

- Совместим с протоколом GPS NMEA, 1 Гц, бод 9600~115200

- GPS «TX» к CRSF-PWM плата «RX» Однопроводное полудуплексное UART соединение, CRSF-PWM плата «TX» к GPS «RX» не является существенным.

- Поддержка GPS телеметрии ID: GPS, GSpd, Hdg, Alt, Sats

- u-blox серии GPS может выводить «0+1 - UBX+NMEA» протокол по умолчанию

- Датчики (GPS, GSpd, Hdg, Alt, Sats) будут мигать на вкладке Transmitter TELEMETRY, как только плата CRSF-PWM установит соединение с GPS.

- Устранение неполадок при отсутствии телеметрии GPS, дважды проверьте проводку между GPS и платой CRSF-PWM, некоторые u-blox GPS могут не выводить NMEA protcol, вам нужно вернуть GPS к конфигурации по умолчанию в u-center.

- С помощью OpenTX Telemetry Logging, Вы можете проложить траекторию полета или найти потерянный самолет.

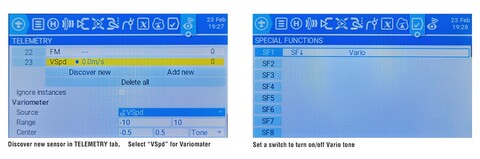

Телеметрия VSpd

- Встроенный барометр SPL06-001 (I2C адрес 0x76)

- Телеметрия VSpd поддерживается ExpressLRS 2.0, EDGE 2.6, OPENTX 2.2 или более новыми версиями.

Частота TIM и ШИМ

- Частота ШИМ на всех каналах 10x может быть настроена в соответствии с TIM

- По умолчанию ШИМ работает на частоте 50 Гц

- TIM2: CH1, CH2, CH4

- TIM16: CH3

- TIM3: CH5, CH6, CH7, CH8

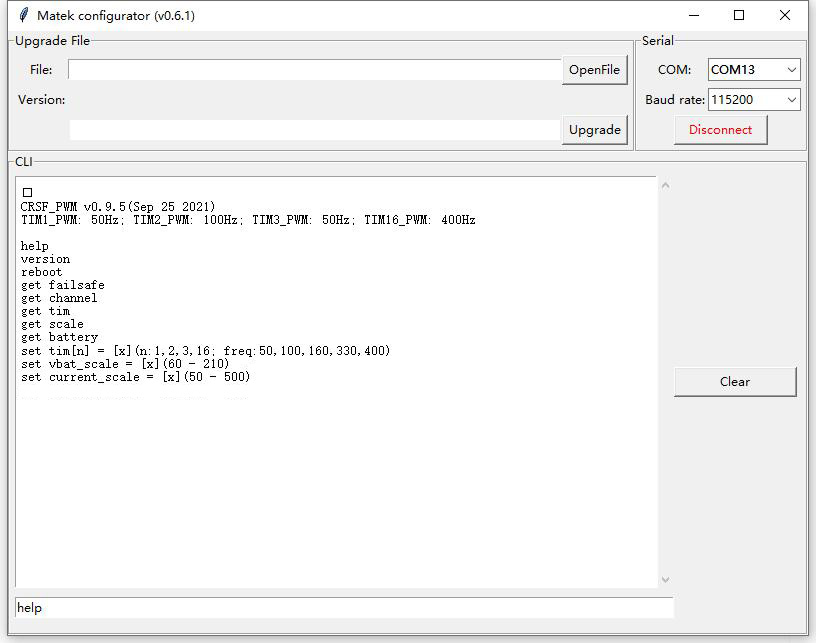

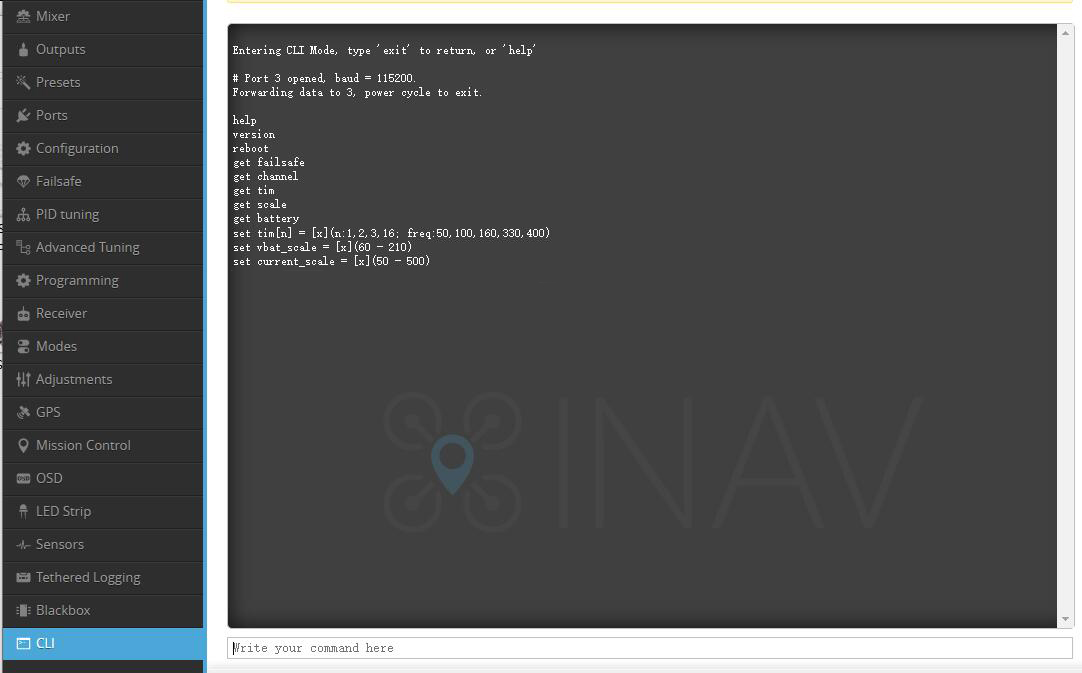

Режим CLI

- Если в течение 10 секунд после включения питания плата CRSF-PWM не обнаружит GPS, подключенный к UART2, активируется режим CLI.

- После включения режима CLI плата CRSF-PWM может быть подключена к конфигуратору через модуль USB-TTL/FC passthrough.

- В режиме CLI можно обновить прошивку платы CRSF-PWM.

- Режим CLI не влияет на сигнал приемника CRSF и выходы ШИМ.

Прошивки

- Для обновления прошивки платы CRSF-PWM-V просмотрите страницу CRSF TO PWM CONVERTER

CLI mode and Parameters

- Tool: Matek Configurator

- via A or B

A. USB-TTL modules, such as CP210x, FTDI

1. Wiring

- TX2 — USB-TTL module RX

- RX2 — USB-TTL module TX

- 4v5 — USB-TTL module 5V

- G — USB-TTL module GND

2. Connect USB-TTL module to PC

3. CRSF-PWM board CLI mode will active after powering on for 10 seconds

4. Open Matek configurator, Select COM port of USB-TTL, Baud rate 115200, Click “Connect”

5. Type command “help”

B. INAV/BF serial passthrough

1. Wiring

- TX2 — FC any spare UART_RX

- RX2 — FC any spare UART_TX

- 4v5 — FC 5V or 4V5

- G — FC GND

2. Connect FC USB to PC

3. CRSF-PWM board CLI mode will active after powering on for 10 seconds

4. open INAV/BF configurator, connect FC to configurator

5. click INAV/BF configurator “CLI” tab, type “serialpassthrough x 115200”, x = UART number -1, e.g. CRSF-PWM board connect to FC UART4, type “serialpassthrough 3 115200”.

6. Type command “help”

************************************************************

*************** Type all command with lowercase ***************

************************************************************

help

List all commands

- help

- version

- reboot

- get failsafe

- get channel

- get tim

- get scale

- get battery

- get baro (fw 2.0.0 or newer)

- set tim[n] = [x](n:1,2,3,16; freq:50,100,160,330,400)

- set vbat_scale = [x](60 – 210)

- set current_scale = [x](50 – 500)

- set output_5 = ch[x](11 or 12)

version

list CRSF-PWM firmware version

- CRSF_PWM App v0.9.5(Sep 25 2021)

reboot

restart CRSF-PWM board

- If receiver is connected and bound to transmitter, Failsafe value will be reset according to the transmitter joystick position.

get failsafe

list failsafe value saved

- PWM CH1_failsafe = 1500;

- PWM CH2_failsafe = 1500;

- PWM CH3_failsafe = 988;

- PWM CH4_failsafe = 1500;

- PWM CH5_failsafe = 1000;

- PWM CH6_failsafe = 1000;

- PWM CH7_failsafe = 1000;

- PWM CH8_failsafe = 1000;

- PWM CH9_failsafe = 2000;

- PWM CH10_failsafe = 2000;

get channel

list all channels PWM value according to joystick position if receiver is connected and bound to transmitter

If receiver is not connected or not bound to transmitter, the CH PWM value = failsafe value saved

- CH1 = 1502;

- CH2 = 1500;

- CH3 = 1007;

- CH4 = 1498;

- CH5 = 1000;

- CH6 = 1000;

- CH7 = 1000;

- CH8 = 1000;

- CH9 = 2000;

- CH10 = 2000;

get tim

list PWM frequency on all TIM

- TIM2 = 50Hz (CH1,2,4);

- TIM16 = 50Hz (CH3);

- TIM3 = 50Hz (CH5,6,7,8);

- TIM1 = 50Hz (CH9,10);

set tim[n] = [x](n:1,2,3,16; freq:50,100,160,330,400)

set PWM frequency on each TIM/CH

- “n” range: 1, 2, 3, 16

- “[x]” range: 50, 100, 160, 300, 400

- TIM2: CH1, CH2, CH4

- TIM16: CH3

- TIM3: CH5, CH6, CH7, CH8

- TIM1: CH9, CH10

- 50Hz by default. Compatible with both old school and modern PWM ESC/servos

- Check ESC and servos datasheet to make sure the ESC and servos can work stably at that PWM frequency you will set.

- Usually Analog servos work at 50Hz only, some digital servos can work at 400Hz. ESC supported by oneshot/DShot can work at 400Hz PWM

- e.g. type “set tim16 = 400”, PWM output on CH3 will run at 400Hz

- e.g. type “set tim2 = 100”, PWM output on CH1, CH2,CH4 will run at 100Hz

get scale

- vbat_scale = 110;

- current_scale = 150;

get battery

list Battery voltage and current, Even if there is no current through the shunt resistor, there may be a certain current reading due to the offset and tolerance of current sensor.

- voltage = 0(mV);

- current = 0(mA);

get baro (fw 2.0.0 or newer)

list barometer altitude and temperature, support MS5611 (I2C address 0x77) and SPL06-001 (I2C address 0x76)

- SPL06: alti = 10(cm), temp = 20(C);

set vbat_scale = [x](60 – 210)

- 1K:10K resistor: 110 by default

- Because of components tolerance you can adjust this to match with multimeter readout.

set current_scale = [x](50 – 500)

- current_scale = 150 by default

- If current readout 10A on telemetry, 10.8A on current meter, you can set the scale to (10.8/10)*150=162

- For using external current sensor on CRSF-PWM-6, You can adjust this value to match with the scale of external current sensor.

set output_5 = ch[x](5/11/12)

- output_5 pin is defined as CH5(AUX1) by default, ELRS AUX1(CH5) is 1-bit / 2-position channel.

- In ELRS 2.0 Wide switch mode, AUX2-AUX8(CH6~CH12) are 7-bit (128 position) for telemetry ratios 1:128 through 1:8, or 6-bit (64 position) for 1:4 and 1:2.

- with this CLI command, You can remap AUX7(ch11) or AUX8(ch12) signal to output_5 pin of CRSF-PWM board. then you will get 128-position channel instead of 2-position on “output 5” pin

Receiver Firmware update

- Receiver has ExpressLRS 2.2.0 preloaded with binding phrase “123456”, the Receiver will never enter binding mode if using the traditional binding procedure.

- It must be flashed without a binding phrase to do traditional binding OR flashed with your binding phrase.

ExpressLRS wiki

Flashing via Wifi

- Disconnect ESC and servos from receiver first.

- Power on receiver by 5V source. Receiver’s LED(Red) will blink slow at first, and after 20s, it should blink fast indicating it’s on Wifi Hotspot Mode.

- More detailed steps, pls refer this page.

- configurator, Target: Generic ESP8285 2.4Ghz RX, or RadioMaster RP1 2.4GHz RX , or HappyModel EP1/EP2 2.4GHz RX

Flashing via UART

- Disconnect ESC and servos from receiver first.

- Wire the receiver into the USB-TTL adapter, with TX on receiver(top board) connected to the Rx on the USB-TTL, and RX on receiver(top board) connected to the Tx of the USB-TTL. Wire 5V and GND of the USB-TTL to 5V and GND of the Receiver.

- Press the boot button while powering on the receiver and CRSF-PWM board, (either button on reeciver board or button on CRSF-PWM-V board). and release – the Red LED on receiver should now be solid. and Blue LED on CRSF-PWM-V should now be fast blink

- configurator, Select the target Generic ESP8285 2.4Ghz RX, (or RadioMaster RP1 2.4GHz RX, or HappyModel EP1/EP2 2.4GHz RX) and “UART” for Flashing Method, set your bind phrase and Firmware Options , Check “erase before flash” and “Force FLash “.

Tips

- Tx/Rx on the top ELRS receiver is for flashing ELRS firmware

- TX2/RX2 for GPS connection or flashing firmware of bottom CRSF-PWM board

| Вес: | 5 г |

| Мощность: | 16 мВт , 12 дБм |

| Производитель: | Matek |

| Протокол связи в микроконтроллерах и периферии: | ELRS , PWM |

| Разъём: | IPEX MHF 1 |

| Частота: | 2.4 ГГЦ |